- Shop No. 20, G. Floor. Farida House, 59/61,

2nd Panjara Pole Lane,

C. P. Tank Road, Mumbai - 400 004.

- Mon - Sat: 09.00 To 18.00

- Sunday Closed

Cupro Nickel

Cupro Nickel

Cupro Nickel

- 90/10 Cupro Nickel is widely used in sea water. It has very good corrosion resistance to clean moderately polluted marine or estuary water, even containing dissolved incondensable gases.

- This alloy is virtually immune from stress-corrosion cracking and hot spot denickelification.

- In clean sea water, a velocity of up 2.2-2.5 m/s (7.5-8.5 ft/s) is accepted while 4 m/s (13 ft/s) is the upper limit for clean fresh or slightly saline solutions.

To avoid the risk of deposit attack, it is generally recommended to never operate at water velocities below about 0.8-1 m/s (2.5-3.5 ft/s). 90/10 Cupro Nickel can also be used, with appropriately reduced flow velocity, in contact with water containing some sulphides or suspended solids. It is also often selected for its good mechanical properties, both at room and relatively elevated temperatures.

- 70/30 Cupro Nickel is mainly preferred when the severity of service condition (Cooling water, steam, condensate, temperature, etc.) is such as to virtually rule out all other copper metals.

- Due to its hardness and to the type of oxide whereby its surface is self-protected, 70/30 Cupro Nickel has excellent resistance to impingement and erosion-corrosion by of suspended solids in sea water flowing at up to 3-3.5 m/s (10-11.5 ft /s).

- Like all Cupro-nickels, 70/30 Cupro Nickel is virtually immune from stress-corrosion cracking.

- It can be very sensitive to deposit attack and is therefore not recommended for stagnant or slow moving (under 1 – 1.2 m/s or 3.5-4 ft/s) water.

70/30 Cupro Nickel is very widely employed in water desalination plants, especially in the most critical areas such as the heat reject and brine heater stages, as well as in the under cooling areas of power station condensers, in the chemical, petrochemical and food processing industries and, more generally, in all applications where top corrosion resistance is required from both the shell and tube side.

PRODUCT APPLICATION AREAS |

|

SIZE |

1/2" to 6' in OD & NB in various SWG & SCH |

FORM |

Round, square, rectangular, coil, ‘u’ shape, pan cake, hydraulic |

LENGTH |

Single random, double random & required length |

END |

Plain end, beveled end, threaded |

MATERIALS |

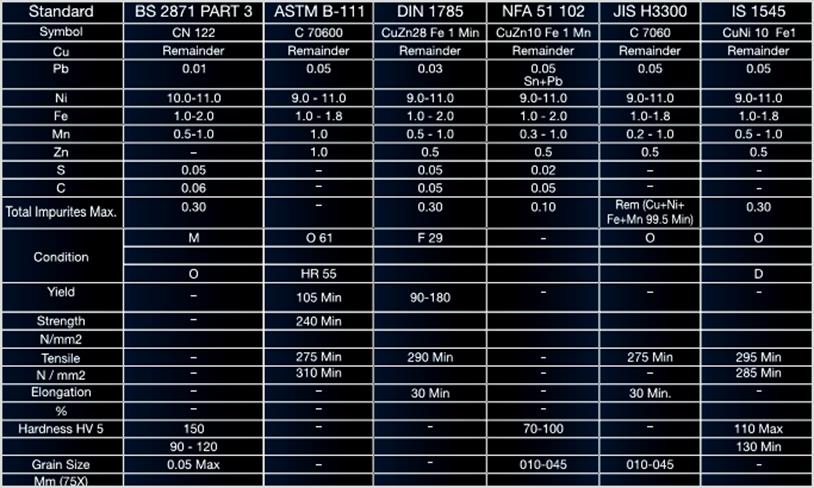

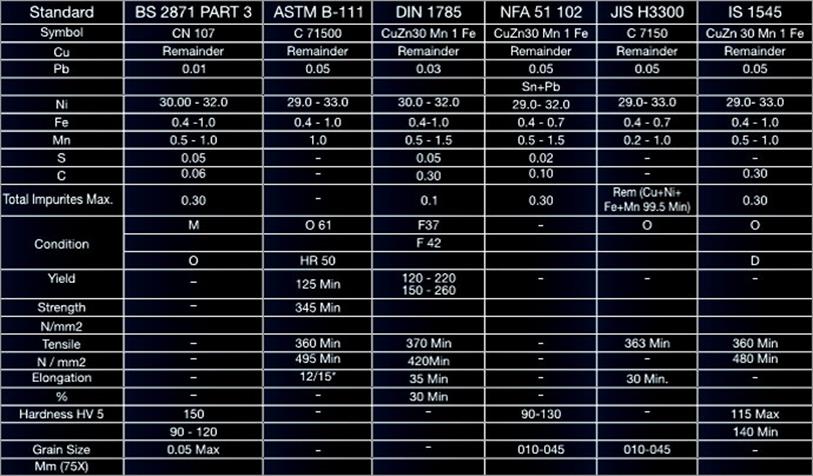

Copper nickel – Cu-Ni Seamless Tube, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) |

- Copper Nickel 95/5 , 66/30/2/2 (C71640)

ALLOY |

STANDARD |

SYMBOL |

95/5 CuNi |

ASTM B 111 |

C70400 |

80/20 CuNi |

ASTMB 111 |

C71000 |

Cunifer |

ASTMB 111 |

C71640 |

PRODUCT APPLICATION AREAS |

|